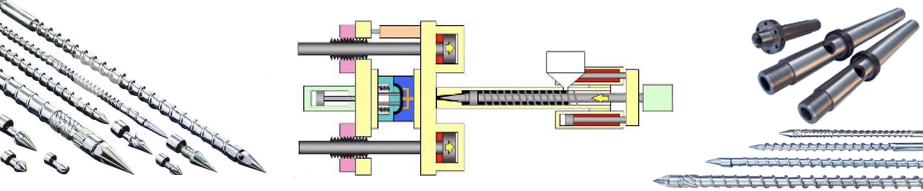

What is the difference between injection molding machine A B C screw?

A Screw: A conventional, gradually - tapered screw. The depth of the screw groove gradually decreases from the feeding to the metering section. This design ensures a stable plastic conveying, compression, and plasticizing process, adaptable to various plastics.

B Screw: A mutant screw with a distinct compression section between the feeding and metering sections. The screw groove depth suddenly decreases in the compression section, subjecting the plastic to high compression force for rapid compaction and plasticization, suitable for high - efficiency plasticization scenarios.

C Screw: A separation - type screw with a separation device near the central shaft, separating solid - plastic transport from melt - plastic transport. This structure enables more thorough plasticization and mixing, enhancing plastic quality and stability.

A Screw: Versatile, meeting most plastics' injection - molding needs. It has a mild shear effect during plasticization, ideal for shear - sensitive plastics like polycarbonate (PC) and polyformaldehyde (POM).

B Screw: Thanks to its mutant structure, it offers high plasticization efficiency, quickly plasticizing and transporting large amounts of plastic. Its strong shearing suits low - viscosity, fluid plastics such as polyethylene (PE) and polypropylene (PP), ensuring better mold - cavity filling.

C Screw: Renowned for its outstanding plasticization and mixing. It thoroughly blends additives and color masterbatches with the plastic matrix, guaranteeing product quality and color uniformity. It also reduces plastic residence time, minimizing degradation risk, suitable for high - quality and color - sensitive injection - molding processes.

A Screw: Besides shear - sensitive plastics, it's suitable for medium - viscosity general plastics like polystyrene (PS) and acrylonitrile - butadiene - styrene copolymer (ABS), ensuring stable injection molding while maintaining plasticization quality.

B Screw: Ideal for high - speed injection of thin - walled plastic products, such as disposable cups and plastic films, where high production efficiency is crucial. It's also used for products with low appearance requirements but strict production - speed demands.

C Screw: Widely applied in engineering plastics injection molding, including nylon (PA), polybutylene terephthalate (PBT), and polyethylene terephthalate (PET). These materials demand high - performance products, and the C - screw's plasticization and mixing ensure excellent mechanical, appearance, and dimensional stability.