Principle: ABS raw materials from different manufacturers vary in performance. Those designed for high - gloss products have optimized rubber - to - plastic phase ratios and particle sizes during synthesis, resulting in better self - gloss.

Operational Advice: Consult suppliers when purchasing. Choose high - gloss ABS grades. Well - known brands' high - gloss ABS can achieve high surface gloss and are easier to control product quality during injection molding.

Principle: Brighteners, like fatty acid esters and amides, form a smooth film on the ABS plastic surface, reducing micro - roughness. They migrate to the surface during plastic melt flow, enhancing surface properties.

Operation Suggestion: Add brightener at a rate of 0.5% - 2%. Test the proportion based on product requirements and brightener type. Use a high - speed mixer for pre - mixing to ensure even distribution before injection molding.

Polishing FinishPrinciple: Polishing the mold cavity and core reduces surface roughness, making the injection product's surface smoother and glossier. Different polishing degrees yield different gloss effects.

Operation Recommendation: For high - gloss products, achieve a cavity surface roughness (Ra) of 0.025 - 0.05μm. Combine manual and mechanical polishing. Start with sandpaper for rough polishing to remove marks, then use a polishing paste and electric polishing machine for a mirror finish.

Hard Chrome PlatingPrinciple: Plating a hard chromium layer on the mold surface offers high hardness, gloss, and wear resistance. It extends the mold lifespan and improves product surface gloss and release.

Operation Suggestion: The chromium plating layer is about 0.02 - 0.05mm thick. Pretreat the mold surface with cleaning, degreasing, and activation to ensure plating quality and adhesion.

Nitriding TreatmentPrinciple: Nitriding forms a hard nitriding layer on the mold surface, making it denser. This reduces plastic melt adhesion, resulting in a smoother product surface and better gloss.

Operating Recommendations: Nitriding temperature is around 500 - 550 °C for 10 - 50 hours, depending on mold size and material. Grind and polish the mold after nitriding to remove surface defects.

Principle: A higher mold temperature keeps the ABS plastic melt fluid, better replicating the mold surface finish and enhancing product surface luster.

Operation Suggestion: For ABS injection molding, raise the mold temperature to 70 - 90 °C. But beware, too high a temperature may prolong cooling time, reduce efficiency, and cause product deformation. Control the mold temperature via the mold's heating device.

Principle: Increasing injection speed helps the plastic melt quickly fill the mold cavity, reducing temperature and pressure drops. Appropriate injection pressure ensures full cavity filling, avoiding surface defects.

Operation Suggestion: Adjust injection speed based on product size and shape, typically around 30 - 60mm/s. Set injection pressure between 70 - 100MPa. Observe product surface quality during debugging to avoid flash and trapped gas.

Principle: Reasonable pressure holding prevents product shrinkage during cooling, ensuring surface flatness and gloss. Proper cooling solidifies the product surface quickly, forming a smooth surface.

Operation Suggestions: Set the pressure - holding pressure at 60% - 80% of the injection pressure. Determine the pressure - holding time based on product wall thickness (about 3 - 5 seconds per millimeter). Adjust the cooling time according to product size and shape to prevent deformation before mold opening.

Principle: In gas - assisted injection molding, high - pressure gas (e.g., nitrogen) is injected into the cavity during plastic melt injection. It helps the melt better fit the mold surface, especially for complex shapes, and reduces internal shrinkage stress, improving product surface smoothness and gloss.

Operation Suggestion: Equip with special gas - assisted injection molding equipment. Determine the gas injection time (usually start when 70% - 90% of the cavity is filled with melt). Adjust gas pressure (5 - 20MPa) according to product size and wall thickness.

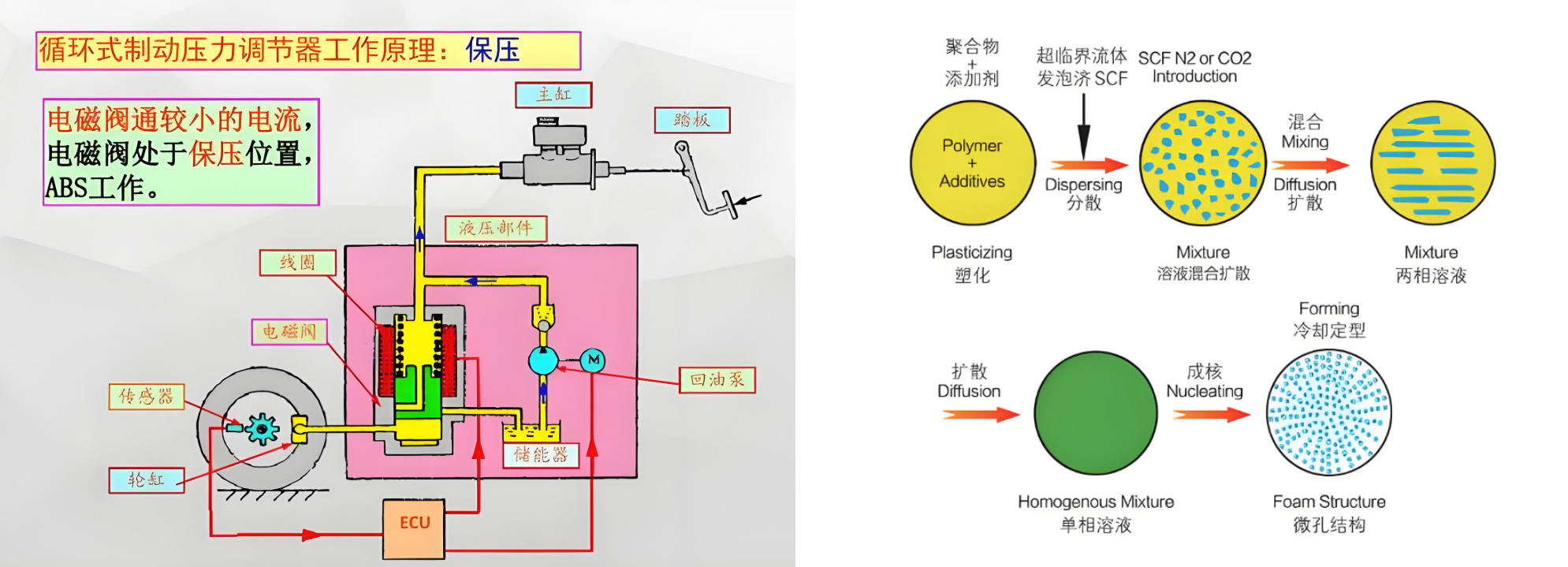

Principle: Microfoam injection involves injecting a physical blowing agent (e.g., supercritical carbon dioxide or nitrogen) into the plastic melt. The tiny bubbles formed improve melt flow and distribution, making the product surface flatter and reducing shrinkage marks, thus enhancing gloss.

Operation Recommendation: Install microfoam injection molding equipment, including a foaming agent injection system and special screw. Precise control of blowing agent injection (0.5% - 3%) is required. Adjust melt temperature (slightly lower than traditional injection molding) and injection speed to ensure uniform foaming.

Principle: The hot runner system keeps the plastic melt molten from the injection molding machine nozzle to the mold cavity. This reduces pressure and temperature drops in the melt flow, providing a stable and uniform melt flow for a smoother product surface and improved gloss. It also reduces waste.

Operation Suggestion: Consider installing a hot runner system during mold design. Choose the appropriate type based on product shape and size. Accurately control the hot runner temperature (190 - 230 °C for ABS). Regularly maintain the system by cleaning and checking heating elements and the runner interior.