Polycarbonate (PC): Offers great optical clarity, high impact strength, and good heat resistance. Ideal for optical lenses, high - end electronics' transparent casings, and car lamp covers. But its poor processing fluidity demands precise process control in injection molding.

Polymethyl Methacrylate (PMMA): Also known as acrylic, has excellent light transmittance like glass and good weather resistance. Used for display racks, light boxes, etc. However, its low surface hardness makes it easy to scratch.

Polyethylene Terephthalate (PET): Widely used in food and drug transparent packaging for its chemical stability, transparency, and reasonable cost. But its crystallization affects injection molding, requiring proper temperature control.

Other Transparent Plastics: Polystyrene (PS) is cheap and transparent, suitable for simple items with low mechanical requirements. Cyclic olefin copolymer (COC) is for high - precision optical lenses, though costly.

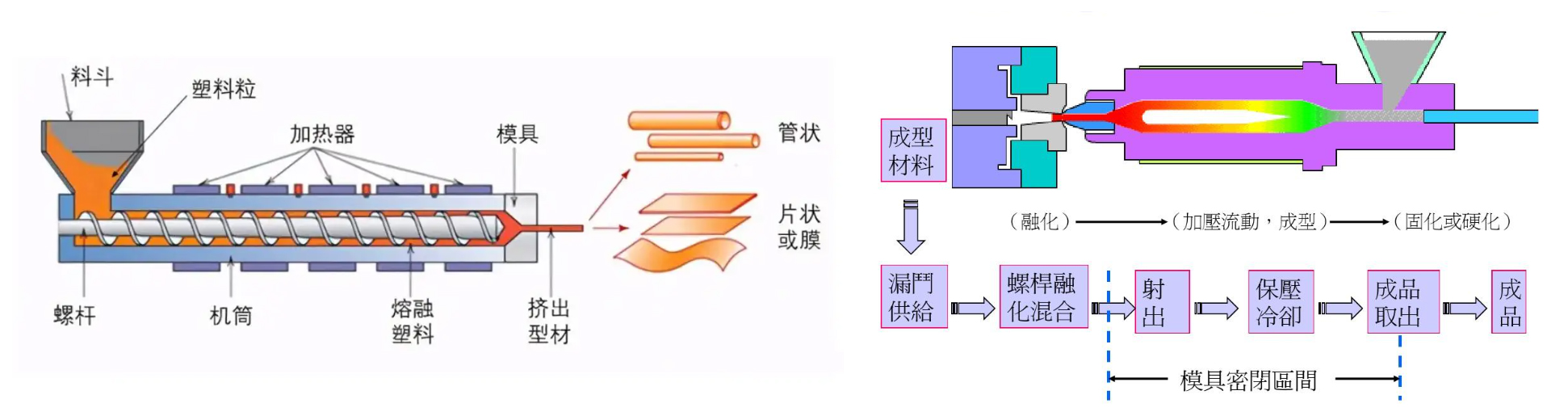

Injection Speed: Keep it slow to avoid turbulence. Use multi - stage speeds for complex products. For simple ones, 10 - 30cm3/s is okay.

Packing Pressure Speed: Set it at 1 - 5cm3/s for stable melt replenishment.

Injection Pressure: Varies by product shape, size, and wall thickness. Thin - walled products need 100 - 150MPa or more; thick - walled ones, 50 - 100MPa. Determine through trial moldings.

Packing Pressure: Usually 60% - 80% of injection pressure for PC, 50% - 70% for PMMA, and 70% - 90% for PET. Adjust packing time (5 - 20s for PC, 3 - 10s for PMMA, 8 - 20s for PET) by trial moldings.

Barrel Temperature: For PC, 260 - 280°C (front), 240 - 260°C (middle), 220 - 240°C (rear). For PMMA, 200 - 230°C (front), 180 - 200°C (middle), 160 - 180°C (rear). For PET, 270 - 290°C (front), 250 - 270°C (middle), 230 - 250°C (rear).

Nozzle Temperature: Slightly lower than barrel front. 250 - 270°C for PC, 190 - 210°C for PMMA, 260 - 280°C for PET.