Polycarbonate (PC) is a high - performance engineering plastic. When reinforced with fibers (e.g., glass fiber), its mechanical properties are enhanced, finding wide use in electronics, automotive, and aerospace. However, the injection molding of fiber - reinforced PC plastics demands strict process control. Here are the details:

Temperature Control

Barrel Temperature Partition: Divide the barrel into feed, compression, and metering sections. Set feed - section temperature at 260 - 280 °C, compression - section at 280 - 300 °C, and metering - section at 300 - 320 °C. Adjust for raw - material batch and fiber - content differences.

Nozzle Temperature: Set it slightly lower than the metering - section temperature, at 290 - 310 °C. Ensure nozzle insulation to prevent melt solidification or drooling.

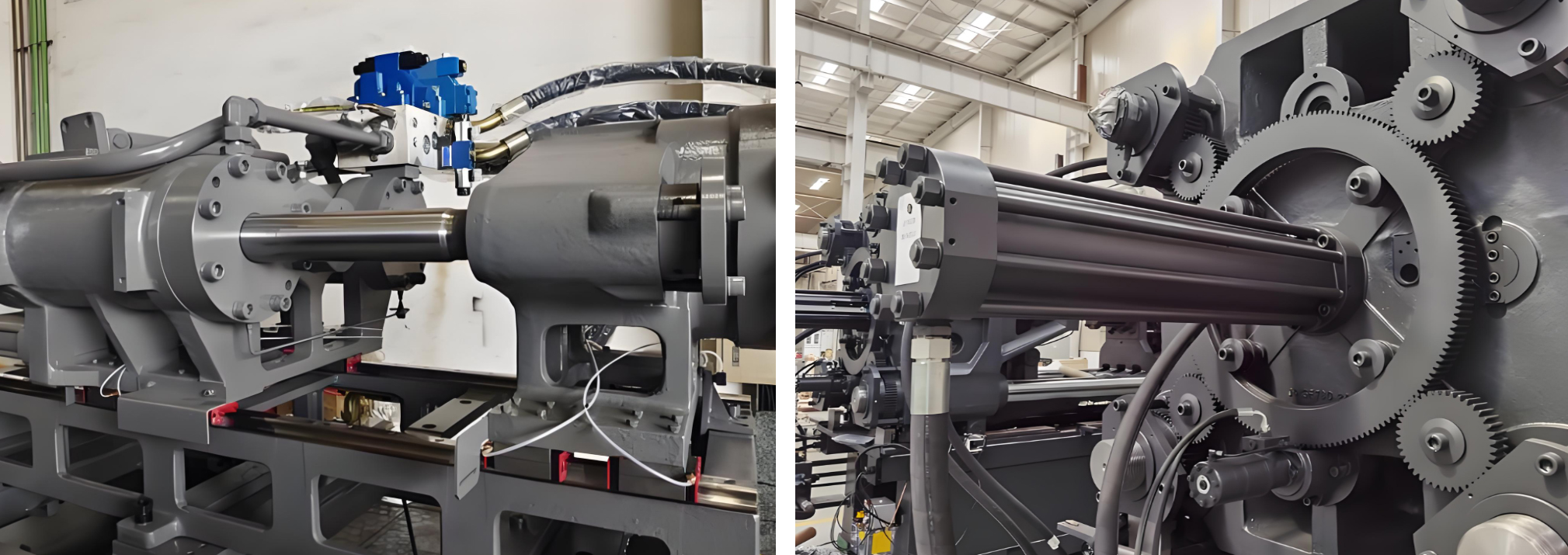

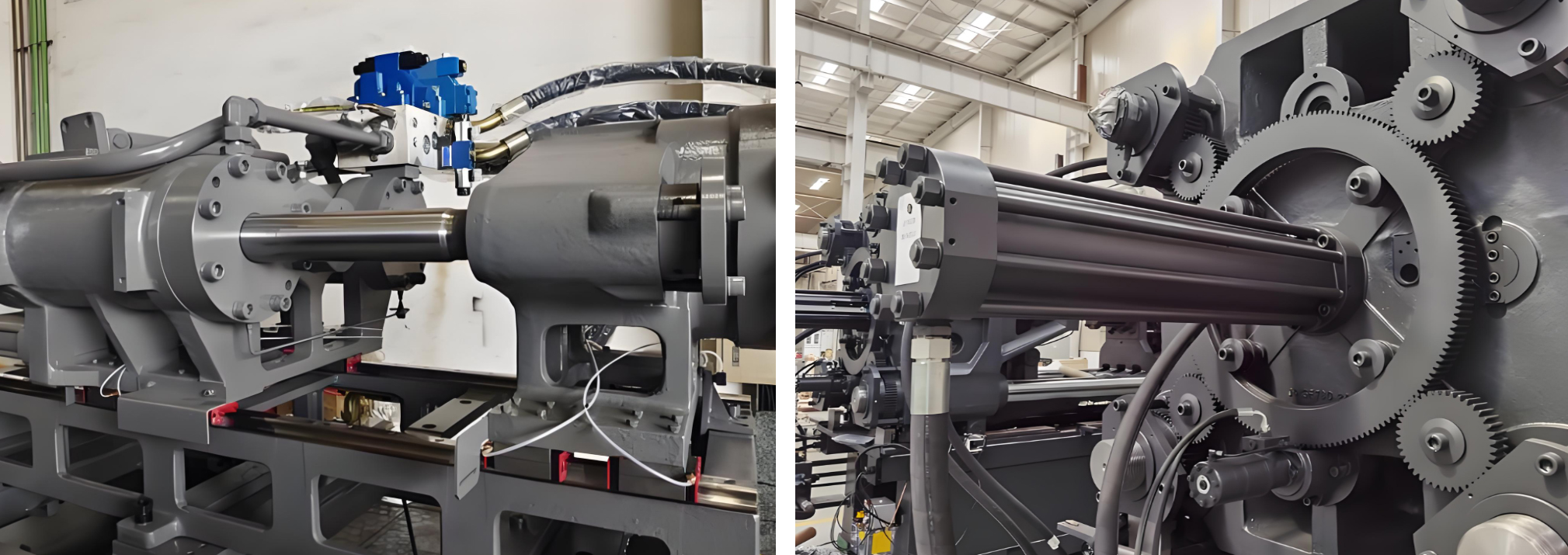

Pressure Control

Injection Pressure Adjustment: Set injection pressure based on product wall thickness, shape complexity, and mold structure. 80 - 100 MPa for thick - walled products (> 3 mm), 100 - 150 MPa for thin - walled (< 2 mm) or complex - shaped products. Fine - tune during injection.

Holding Pressure Setting: Holding pressure is 50% - 80% of injection pressure. Increase for large or thick - wall products. Determine holding time according to product thickness (1 - 2 seconds per 1 mm increase in wall thickness).

Speed Control

Injection Speed Curve: Control injection speed in multiple stages. Start with a low speed (10 - 30 mm/s), increase to 30 - 60 mm/s when 50% - 70% of the cavity is filled, and reduce to 10 - 20 mm/s near the end.

Screw Speed Control: Keep screw speed at 40 - 60 r/min for fiber - reinforced PC to ensure good plasticization without breaking fibers.

Gate Design

Type Selection: Use pin - point gates for high - appearance - quality, small - size products (0.8 - 1.5 mm diameter). Side gates are suitable for flat or simple - shaped products (width 1 - 2 times wall thickness, depth 0.6 - 0.8 times wall thickness).

Location Optimization: Set the gate in thicker - walled product parts, away from stress - sensitive and appearance - critical areas.

Runner Design

Main Runner Design: The main runner has a 2° - 4° taper, with the small - end diameter 0.5 - 1 mm larger than the nozzle diameter. Keep it short and ensure a smooth transition to the diverter.

Diverter Design: Determine diverter diameter (4 - 8 mm, larger for large products or multi - cavity molds) and use round or trapezoidal sections. Ensure low surface roughness.

Annealing Treatment

Parameter Determination: Anneal at 120 - 130 °C (up to 140 °C for thick - wall products) for 1 - 2 hours per 1 mm of wall thickness. Heat slowly (10 - 20 °C/hour) in an air - circulation oven.

Effect Evaluation: Evaluate annealing by observing product appearance and size changes. Use a polarizing stress meter to detect internal - stress reduction.

Surface Treatment

Grinding and Polishing: Remove gate marks and flash by grinding, then polish (mechanically, chemically, or electrolytically) to improve gloss.

Coating and Plating: Coat to enhance appearance and protection. Pretreat the product surface. Electroplate to add metallic properties, controlling plating parameters.

In conclusion, the injection molding of fiber - reinforced PC plastics is a complex process. Every step, from pre - injection preparation to quality testing, is interrelated. Strictly controlling each process detail is crucial to produce high - quality products that meet performance requirements across various applications.